ESG Software for manufacturing industries:

Over the past 25 years, there has been a remarkable rapid transformation in the industrial landscape worldwide. The manufacturing industry is also on the verge of such an industrial revolution, driven by increased competition, changing customer expectations, supply chain challenges, and natural challenges like global warming and climatic changes.

These challenges force renewed changes across the industry, encouraging manufacturers to adopt new sustainability practices for their manufacturing portfolio, such as performance tracking, data quality, supply chain, and scope-3 emission, as consumers become more aware of the environmental impact of their purchasing decisions.

As a result, it is affecting their choices. In response, businesses are making concerted efforts to implement more sustainable manufacturing practices. Let's explore five areas where manufacturers can achieve more sustainable practices while keeping their businesses profitable. Manufacturers are urged to make magnificent strides to maintain their sustainability practices.

Why is ESG necessary for manufacturing?

The necessity of ESG (Environmental, Social, and Governance) practices has become even more apparent in light of recent devastating climate changes. Businesses today face significant challenges such as excessive carbon emissions, water scarcity, limited fossil fuel availability, extreme weather conditions causing service disruptions, inefficiency, and waste management.

Adopting best ESG practices at all stages of your business model, including production, design, R&D, quality, and procurement, helps improve overall efficiency and reduce emissions and wastage, resulting in profitable revenue and enhanced reputations.

Compared to other industries, manufacturing industries are more likely to mount pressures from legislators, investors, and consumers, affecting multiple fronts like supply chains, labor laws, gender diversity, and many more. Therefore, updapt sustainability software for manufacturing industries that cover various types of emissions, such as upstream and downstream emissions.

What is ESG for a Manufacturing Company?

ESG implies environmental, social and governance is a set of frameworks which help to evaluate organization performance in sustainability. Environmental metrics are more important, especially manufacturing industries such as.

- Greenhouse Gas Emissions.

- Energy Consumption.

- Water Usage.

- Waste Management.

Addressing ESG Challenges in the Manufacturing Industry:

Carbon Emissions (Scope 3 Emissions): Manufacturing processes are energy-intensive, leading to high levels of carbon dioxide and other greenhouse gas emissions. Reducing these emissions is crucial for mitigating climate change and meeting regulatory standards.

Data Collection and Integration: ESG data encompasses environmental, social, and governance metrics. Environmental data includes water and energy consumption, greenhouse gas emissions, air emissions, and waste management. Consolidating all these metrics into a centralized system is challenging but essential for effective management.

Data Accuracy: Inaccurate data can negatively impact brand reputation, investment decisions, ESG risk management, and regulatory compliance. Ensuring data accuracy is paramount.

Various Emission Sources: Scope 3 emissions come from various sources such as waste disposal, employee commuting, and transportation and distribution. Incorporating these emission sources into reporting and measurement is complex but necessary for comprehensive ESG management.

Supplier Emissions: Supplier emissions, part of Scope 3 emissions, are associated with production, transportation, and distribution within the supply chain. Managing these emissions can be complex when suppliers do not adhere to ESG standards.

Value Chain Partner Emissions: Value chain emissions cover all stages from raw material extraction to production, transportation, distribution, use, and disposal. Understanding and measuring these emissions can be complex but is essential for accurate reporting.

How Updapt Addresses These Challenges:

Comprehensive Digital ESG Tools: Updapt offers various SaaS ESG tools that cover all sustainability needs for the manufacturing industry. Its software is designed with various reporting KPIs suitable for small, medium, and large enterprises.

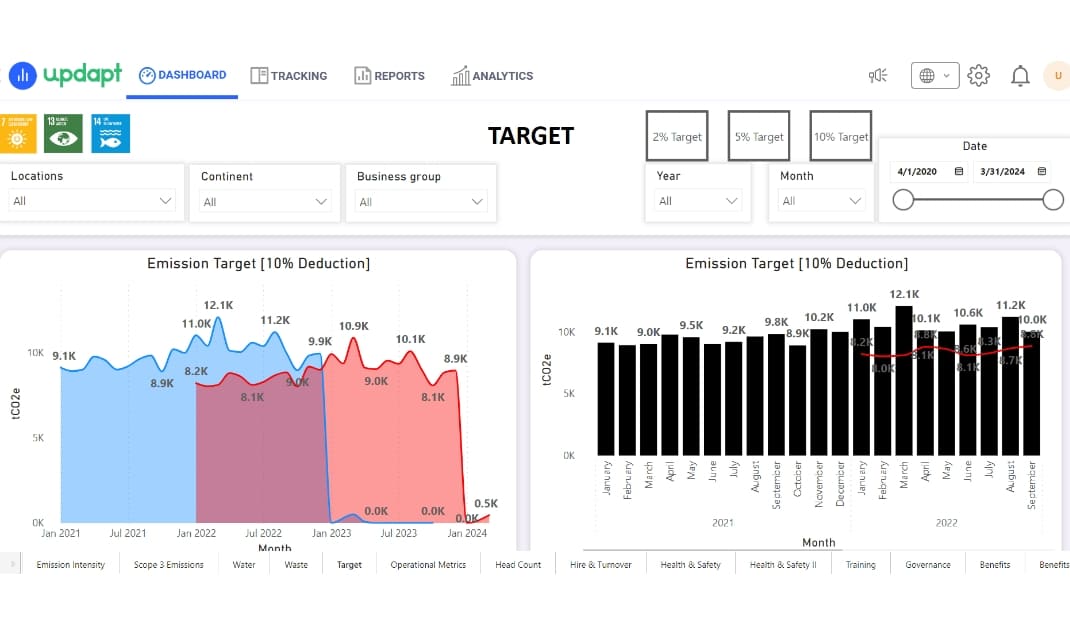

Data Solutions: Data is crucial for measuring Scope 3 emissions. Updapt's ESG data management tools ensure high-quality data collection, consolidation, and monitoring.

Effective Data Management: Updapt's ESG software effectively collects all ESG data and consolidates it into a centralized system. The software ensures data quality, reducing ESG risk. Key features include:

- Data consolidation

- Streamlined data processes

- Easy integration

- Ensured data quality

- Centralized repositories

Scope 3 Emissions Management: Updapt's software measures supplier and value chain partner emissions as part of Scope 3 emissions, a critical metric for transparent reporting. The platform simplifies the process of measuring and managing Scope 3 emissions.

Other Benefits of incorporating ESG in manufacturing portfolio:

Implementing ESG has several benefits for manufacturing organizations. Among them, cost savings are prominent.

Reputation:

Adopting ESG practices efficiently and contributing to green gas emission reduction could help organizations create a better reputation among investors and stakeholders.

Risk management :

Regardless of the size of your manufacturing organization, incorporating ESG risk management metrics into your business is a prudent decision. Traditional risk management typically focuses on evaluating and addressing financial and operational risks.

In contrast, ESG risk management involves assessing an organization's environmental, social, and governance-related risks. This includes evaluating factors such as labor practices, corporate governance, environmental impact, and more, ensuring a comprehensive approach to risk evaluation.

Obtain the valuable capital:

ESG asset value is gradually increasing and Investors seek out potential ESG stocks. Therefore, before investing investors evaluate the ESG stocks with the help of the organization's ESG report.

So, enhanced ESG reports always pave the way to gain potential investors.

Aids Better Business Decisions:

Quality ESG data provides meaningful insights and better data into your business, eventually helping in the decision-making process, and leading to better outcomes.

ESG Software for manufacturing Industries, Updapt is an ESG Tech Support all the global sustainability and esg standards, Book a demo now to know more.

- Carbon disclosure project(CDP).

- Integrated Reporting Framework.

- Task Force on Climate-related Financial Disclosures (TCFD).

- Global Reporting Initiative(GRI).

- Sustainability Accounting Standards Board (SASB).

Updapt-esg-all-in-one-sustainability-software

Buyers Guide of ESG Data management, Reporting & Analytics software for manufacturing companies in Middle East countries.

Reporting :

Manufacturing industries should be more conscious of Environmental impact than the other industries. Ensure, Before choosing a sustainability software for manufacturing portfolio, it should be compatible with KPIs.

Water management:

Track and measure waste generation, and recycling rates along with waste reduction strategies.

Water usage:

Must measure Water consumption as well as encompass strategies for reducing water usage.

Environment compliance:

Manufacturing industries pay more attention to environmental compliance. In that respect, tools must be up to date based on the geography.

Air Emission:

Air emissions have a sum amount of impact on the environment. Whereas, many countries insist organizations must add air emission metrics to their ESG reporting. It helps avoid legal fines and penalties.

ESG Software Pricing Option:

Free Trial for one week or one day, Monthly Subscription and Free Demo .

Integration Support for different types of organizations and multi-level integration.

Aligning to global standards of reporting such as GRI, BRSR, TCFD, CDP, and CBAM Reporting.

In a nutshell:

Environmental and societal changes continue to have an impact on manufacturing operations. Organizations that can adapt to this changing terrain will be better positioned and outperform in the long run.

In addition, organizations cannot get potential investors without enhanced ESG Reporting. Therefore, Updapt ESG reporting software precisely comprehends the manufacturing industry's problem and bestows various emission reduction strategies which include data and ESG framework solutions.